Human Expertise + API Efficiency

High End Separations

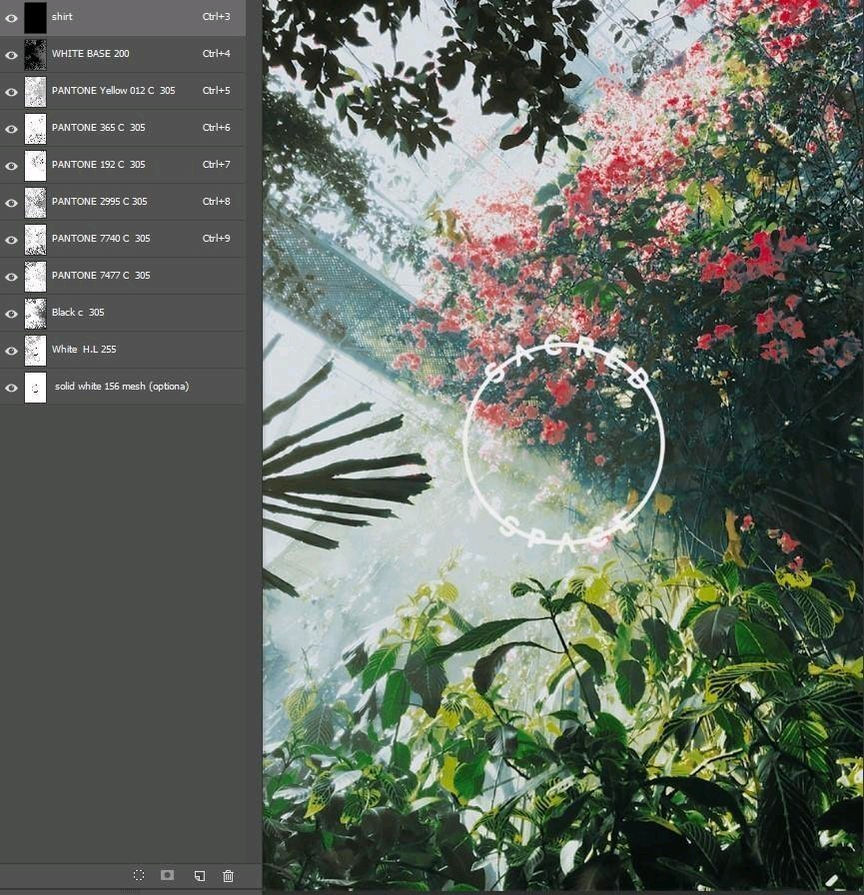

Simulated Process |

Spot Color Process. |

Four Color Process

What We Offer:

Precision-Driven,

Print-Ready Color Separations for Perfect Results

Simulated Color

Perfect for photorealistic and detailed designs for flexibitility.

Spot Color Process

Ensuring solid, vibrant prints with minimal ink waste

Four-Color Process

For full-color, highly detailed prints with perfect registration following CMYK.

ABOUT US

We carefully manage color transitions, halftone placement, and underbase structure — so your prints come out clean, consistent, and visually stunning.

Why Choose Us?

We fine-tune every detail, maintaining color accuracy and vibrancy for consistent, professional results on every print run.

Tight Registration Tolerance – Cleaner prints, fewer misprints.

Deep Blacks, Smooth Halftones, Accurate Gradients - Every detail matters.

Artist-Led Adjustments – Our team of seasoned print designers manually adjust every file.

Press Specific Optimization - We turn your files to your equipment and ink system.

Benefits of Using Our Service

Each separation is manually aligned for tight registration, reducing the chance of misaligned prints. Your presses run smoother, faster, and require fewer adjustments between shirts.

Our files are labeled and pre-structured to match your specific screen setup. With fewer unknowns and no guesswork, your press team can burn screens and get to print faster.

We don’t rely on auto-seps. Every gradient, transition, and shadow is adjusted by real artists to ensure clean blends and smooth fades — especially on dark garments.

Accurate underbases, proper color layering, and optimized screen counts mean fewer misprints and spoiled garments. No more trial-and-error on press.